Specialized in:

- Rigid endoscopes: large choice of superalloys for urology, arthroscopy, laparoscopy…

- Flexible endoscopes: tubing for articulation joints

- All other material for tubular components: AISI 304, AISI 316, Monel

Minitubes advantages:

- In-house tubing and component production

- A choice of PH grade materials: MP35N, Phynox, 17.7

- Very strong mechanical properties, UTS up to 2000 Mpa

- High dimensional accuracy

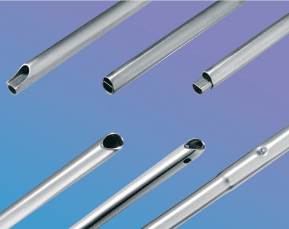

- Round, oval, square, stepped tubing

- End forming, polishing, assemblY

At your service:

- From single components to complex assemblies

- From the design step to serial production

- Eager to develop new processes to meet your technical and ramp-up requirements

Minitubes, from the design stage to final assembly:

Minitubes, from the design stage to final assembly:

- We will work with you to develop your endoscope design: our experience in problem solving is available to meet your specific technical challenges.

- Express prototyping: quick turnaround at the design stage. To quickly test your ideas, our dedicated team will produce your prototypes, with in-house tubing production, CNC component machining, fabrication and assembly.

- Fully integrated tubing production, to control the key parameters, such as surface finish, dimensional accuracy and material for small and larger quantities.

- Choice of materials, because stainless steel is not always the best answer to your requirements for corrosion resistance, strength, magnetism.

- Special alloys designed for thin wall but very stiff tubing.

- Various geometries, optimized for your specific use: multichannel, side hole…

- A variety of fabrication processes: Swiss turning, bending, swaging, flattening, drilling, EDM cutting or machining, punching…

- Surface control: buffing, electropolishing, passivation, coatings…

- A variety of assembling techniques: welding, laser, plasma, TIG, brazing / soldering / glueing / crimping…

Quality assurance at its best: ISO 9001-2015 and ISO 13485-2016.

SMALL TUBES – HIGH TECHNOLOGY

SMALL TUBES – HIGH TECHNOLOGY