Applications

Does your application require precision metal tubes? We offer tailor-made solutions.

With diameters from 0.10 to 35 mm, thick or thin walls, and over 100 available alloys, we offer tubes and tubular components for the most demanding industries.

Minitubes masters a range of techniques to provide innovative solutions, from design to the production of prototypes and large series: tubes for stents, diagnostic needles, hypotubes, surgical instruments, valves, pacing components…

Cardiovascular Implants

STENTS, ELECTRODES, ORTHOPEDICS

- Unique quality designed for the specific requirements of implants. Lives depend on it.

- High selectivity of raw material sources.

- Seamless tubes, highly concentric, very high precision.

- Optimized surface finishes.

- Full certification for each batch.

Materials

Stainless steels, 316 LVM and nitrogen-strengthened grade

Exceed standard requirements, particularly for inclusions.

316 LVM stock: Over 200 references immediately available.

Cobalt-based alloys with very high mechanical properties

L605 ®- Alloy 25 ®- Alacrite XSH ® = Co-Cr-W-Ni-Fe. Tungsten enhances radio-opacity.

MP35N ® = Co-Ni-Cr-Mo, combines high mechanical properties and good ductility in the annealed state

Elgiloy ®- Phynox ® = Co-Cr-Ni-Mo-Fe. Very high yield strength, a long history of implantation

Tantalum

Very good radio-opacity, MRI compatible.

FOR SMALL QUANTITIES AVAILABLE QUICKLY:

Implantable Stock List

Precious metals and their alloys

Gold, platinum, platinum iridium: they combine radio-opacity and electrical conductivity.

Special alloys on request

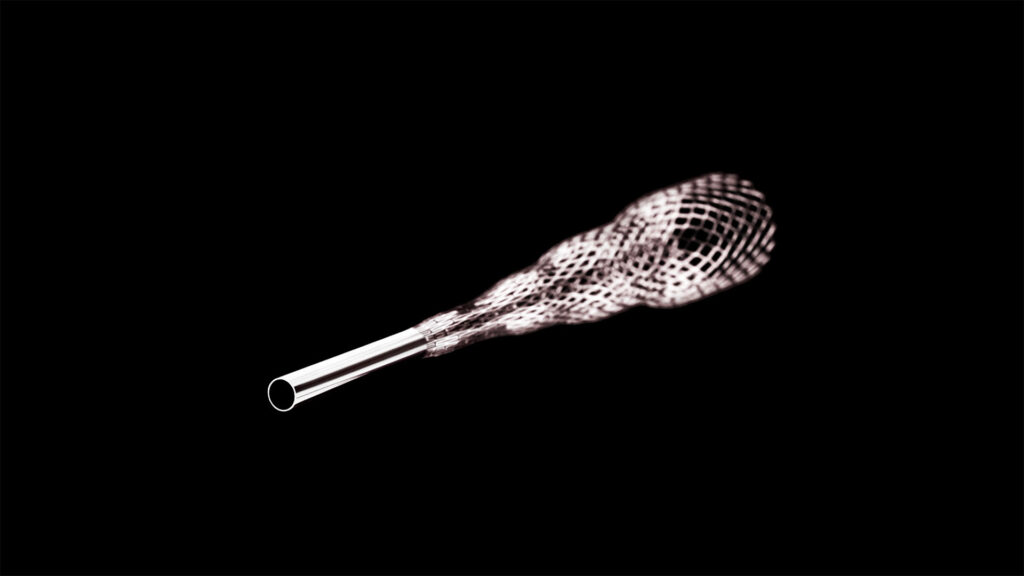

Featured products: stents

Vascular implants made from laser-cut tubes, stents and heart valves require tubes of a very high level of quality and performance.

Minitubes offers tubes for implants of unique quality, specific to stents and heart valves, in several alloys including 316LVM and cobalt bases.

It is this quality that allows us to supply the world’s leading stent manufacturers. We produce tubes that meet the most demanding criteria:

- A wide choice of alloys,

- Careful material selection: biocompatibility, mechanical properties, and overall stent performance depend on the raw material,

- Seamless tubes exclusively: although also a producer of roll-welded tubes, we consider them too risky for stents,

- Dimensional precision and flawless internal and external surfaces for optimized laser cutting and polishing,

- Complete certificates for raw material and finished product.

Various dimensions, in small quantities, are immediately available: Implantable Stock List

For any technical questions and special alloys, contact us

Tubes for heart valves

With over 15 years of experience in the field of tubes for heart valves, MINITUBES offers the perfect tubing solution for your balloon for the development of your balloon-expandable valve.

- Straightness ≤ 2 mm/m for consistent laser cutting.

- Tight control of outer diameter +/-0.05 mm for easy processing.

- CoCr *MP35N quality proven for biocompatibility and cleanliness. Other materials available on request.

- Constant WT +/-0.02 mm for uniform behavior.

- Controlled mechanical properties for consistent crimping and deployment.

- Smooth OD and ID surface Ra < 0.2 µm for device finishing.

- Support and deliveries worldwide.

- Support for your development, from prototypes to commercial volumes.

- Rigorous inspection and official certification.

- Dedicated raw material stock to reduce lead times.

- Prototype with customized dimensions and properties within 4 weeks.

- Stock tubes available within 1 week – Most common sizes available.

The contractual requirements applicable to our THV tubes are defined in standard specification CDC-05975 (available on our website). Do you need tubes with unique properties for your delivery systems?

Contact us, we have solutions!

Life Sciences

- Needles for in vitro diagnostics. Our mastery of tube surface finish and unique experience enable us to solve problems of contamination, heating, level detection, septum piercing, etc.

- Endoscopes: the use of remarkable materials optimizes their performance.

Surface finish control

Controlling the internal surface finish allows for unique performance in critical applications, particularly for IVD probes. Electropolishing, dynamic passivation, mechanical polishing, honing, wide choice of coatings…

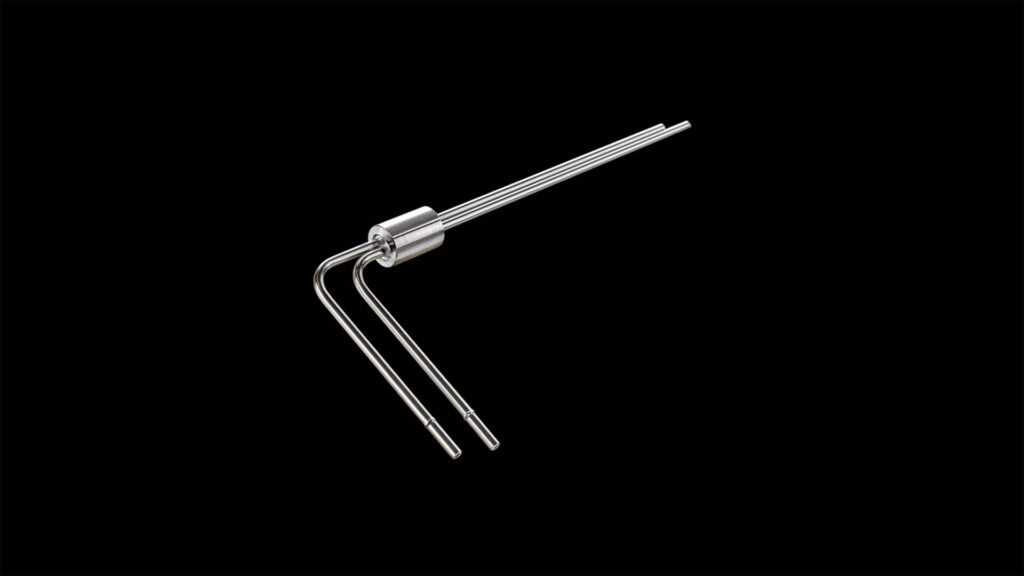

Probe geometry

The precision and repeatability of sampling depend directly on the geometry and surface finish of the pipetting tips.

The tip shape and its surface properties influence the contact area between the sample and the pipette, which can affect droplet formation.

Conical tips are designed according to the volumes to be sampled. Minitubes has developed an exclusive process to obtain a very smooth internal surface, both in cylindrical areas and in transition cones, without limitation on the length of the stepped sections.

Septum piercing

Septum piercing imposes technical constraints in terms of mechanical resistance, wear, ventilation, and anti-corundum design.

- Mechanical resistance: reinforced by the use of a cobalt-chromium alloy and a robust connection between the tubular pipette and its collar (laser welding or brazing).

- Wear resistance: achieved through surface treatments such as coatings (hard chrome, TiN, DLC) or ion implantations (kolsterizing).

- Ventilation: made possible by machined longitudinal grooves, the use of multi-lumen tubes, or by separating functions via a sampling probe circulating inside a piercing needle.

- Non-corundum tips: specific geometries such as pencil point, side cut, or adapted bevel.

ENDOSCOPY

Specialties:

- Rigid endoscopes: wide choice of superalloys for urology, arthroscopy, laparoscopy…

- Flexible endoscopes: tubes for articulation joints.

- Any other material for tubular components: AISI 304, AISI 316, Monel.

Advantages of Minitubes:

- In-house production of tubes and components;

- A choice of PH (precipitation hardening) quality materials: MP35N, Phynox, 17.7;

- Very strong mechanical properties, UTS up to 2000 MPa;

- High dimensional precision;

- Round, oval, square, and stepped tubes;

- End forming, polishing, assembly.

At your service:

- From individual components to complex assemblies;

- From design to series production;

- Development of new processes to meet your technical requirements and ramp-up needs.

Minitubes, from design to final assembly:

- We work with you to develop your endoscope design and offer our problem-solving expertise to meet your specific technical challenges.

- Express prototyping: a rapid turnaround at the design stage. To quickly test your ideas, our dedicated team will produce your prototypes, with in-house tube production, CNC component machining, manufacturing, and assembly.

- Fully integrated tube production, to control key parameters such as surface finish, dimensional precision, and material for small and large quantities.

- Material selection, because stainless steel is not always the best answer to your requirements for corrosion resistance, strength, and magnetism.

- Special alloys designed for thin-walled but very rigid tubes.

- Various geometries, optimized for your specific use: multi-channel, side holes…

- A variety of manufacturing processes: Swiss turning, bending, swaging, flattening, drilling, EDM cutting or machining, punching…

- Surface control: polishing, electropolishing, passivation, coatings…

- A variety of assembly techniques: welding, laser, plasma, TIG, brazing / soldering / bonding / crimping…

Quality assurance at its best: ISO 9001-2015 and ISO 13485-2016.

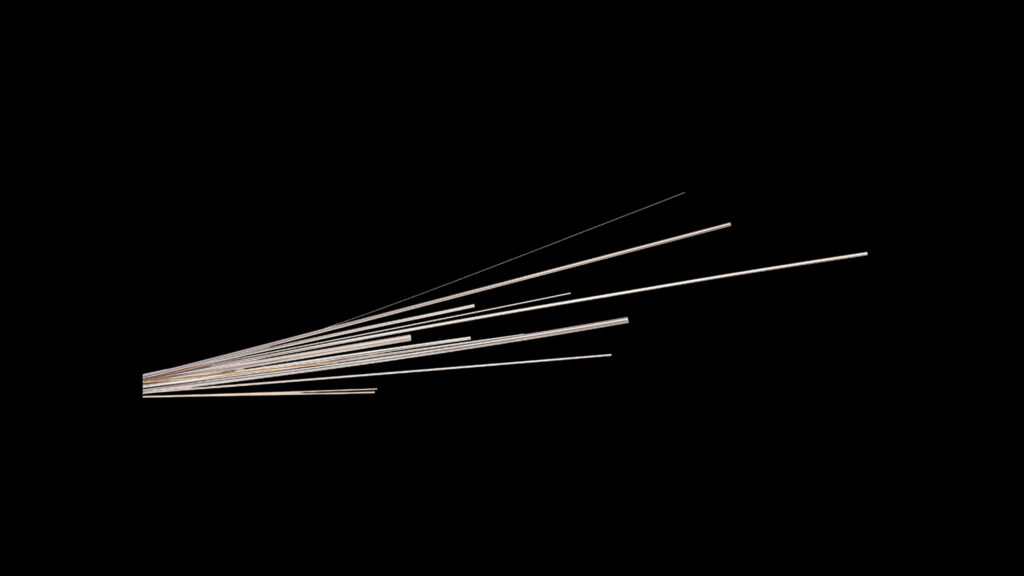

Catheters and delivery devices

Custom manufacturing of catheter tubes and medical device delivery systems

- Utilizing various metal drawing technologies, ranging from coil drawing to straight bench drawing,

- Including secondary operations such as wire cutting or electrochemical cutting, passivation, coatings…

For your applications, Minitubes develops industrial solutions based on extensive metallurgical expertise and drawing experience:

- To obtain a superior external surface and ultimately facilitate coating

- To ensure torque transfer, flexibility, and pushability, while avoiding kinks, maintaining the initial shape, and improving maneuverability and balloon inflation speed.

- With small metal tubes in a wide choice of alloys: stainless steel, cobalt chrome, Inconels, nickel alloys,…

- By guaranteeing the material’s potential within strict specifications: dimensions, mechanical properties, microstructure, surface finish, hardness…

- Validated by batch reports and certificates of conformity.

Field of application: cardiovascular, neurovascular, structural heart, yours?

At your service, a dedicated product and process development team,

supports you throughout the product lifecycle, from rapid prototype iterations

through to qualification and large-scale production

Industrial Technologies

Tubes and parts for other medical applications, aerospace, defense and space, automotive, electronics, and watchmaking.